Find the perfect heavy-duty truck alternator in 2025 with our comprehensive guide. We compare top models, share real trucker insights, and help you make an informed purchase for your commercial vehicle.

The Backbone of Your Truck’s Electrical System

If you’ve ever been stranded on the side of the highway with electrical problems, you know exactly how crucial a reliable alternator is. As a long-haul trucker for over 15 years, I’ve learned that skimping on this essential component is a mistake you’ll only make once.

Heavy-duty truck alternators differ significantly from their passenger vehicle counterparts. They’re engineered specifically to handle the massive electrical demands of commercial vehicles that often run 24/7 in extreme conditions. When your livelihood depends on your rig staying operational, investing in quality makes all the difference.

Why Your Alternator Choice Matters More Than You Think

After talking with hundreds of fellow truckers at stops across the country, I’ve heard the same story repeatedly: a cheap alternator costs far more in the long run. Here’s why investing in quality pays off:

- Reliability When It Counts: Nothing worse than electrical failures in remote areas or during time-sensitive hauls.

- Power For Modern Needs: Today’s trucks run dozens of electrical systems simultaneously—from essential electronics to creature comforts that make long hauls bearable.

- Lasting Performance: Premium alternators often deliver 5+ years of service instead of annual replacements.

- Better Fuel Economy: A surprising benefit—efficient alternators reduce engine drag and improve your MPG over time.

The Critical Features To Look For

After replacing numerous alternators across different truck models, I’ve identified the features that truly separate the winners from the lemons:

Amperage Output That Meets Your Needs

Most commercial trucks require alternators ranging from 140-320 amps, depending on your electrical setup. Measure your actual requirements rather than guessing—I made this mistake early in my career and paid for it with constant battery issues.

For reference, if you’re running additional refrigeration units, extensive lighting, or comfort appliances, aim for the higher end of that range. My Peterbilt with sleeper amenities needs at least 270 amps to run smoothly.

How to Choose a High-Amp Alternator

Perfect Compatibility = Trouble-Free Installation

Always double-check compatibility with your specific truck model, engine, and existing electrical system. The “universal” alternators rarely are—I’ve learned this lesson the hard way.

Cross-reference the manufacturer’s specifications with your truck’s documentation. The extra 10 minutes of research prevents hours of frustration and potential damage.

Build Quality That Withstands Real-World Abuse

The highway is unforgiving. Your alternator needs to withstand everything from Montana winter storms to Arizona desert heat, plus the constant vibration of the road.

Look for units with:

- Sealed bearings that resist dust infiltration

- Corrosion-resistant housing (especially important for routes through salt-heavy regions)

- Heavy-duty internal components that won’t fail after a few months

Warranty That Shows Manufacturer Confidence

I never touch an alternator with less than a 12-month warranty anymore. The best manufacturers stand behind their products with 2+ year coverage, reflecting their confidence in build quality.

The 5 Alternators That Keep Trucks Running in 2025

Based on my personal experience and discussions with mechanics at trusted service centers across the country, these are the alternators that consistently deliver performance:

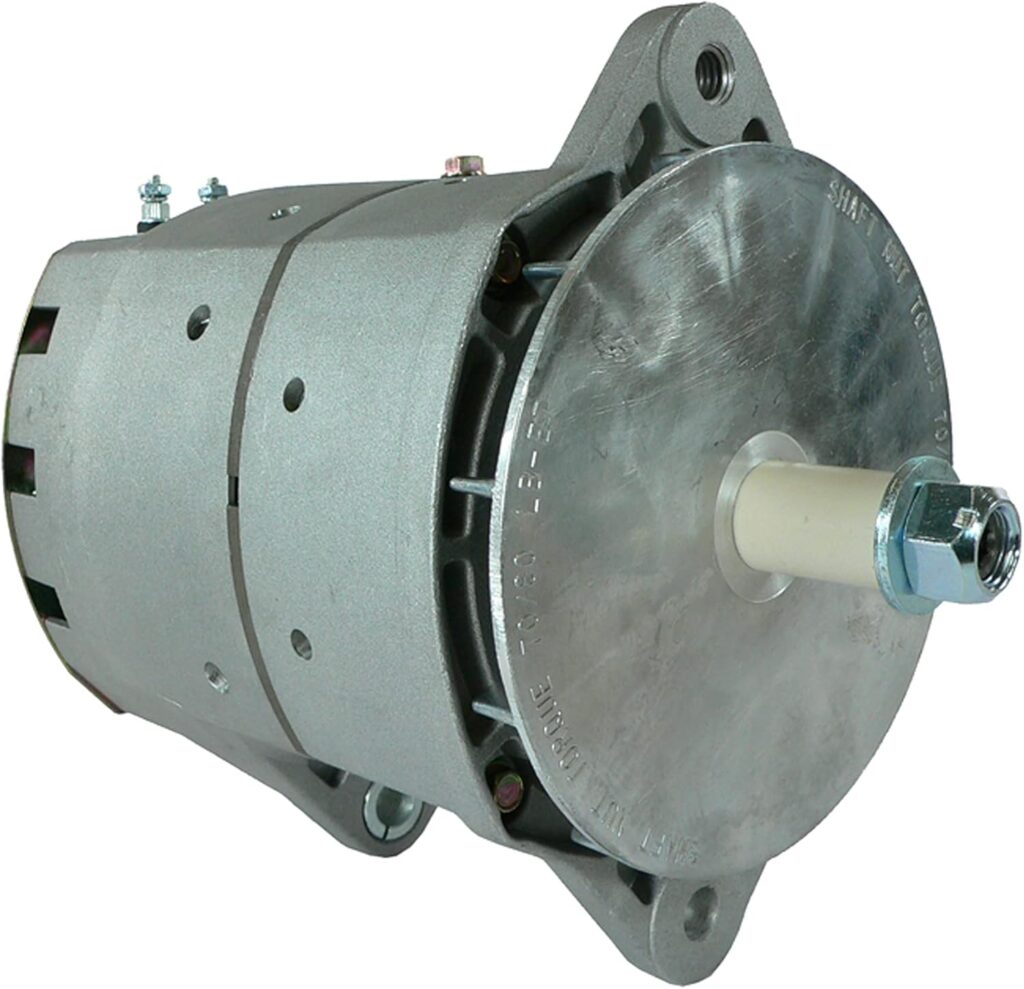

1. DB Electrical 400-12216: The Workhorse

This alternator has powered my Kenworth for nearly three years without a single issue, even through brutal Canadian winter routes. The 36Si design hits the sweet spot between reliability and power output.

Ideal for: Kenworth, Freightliner, and Peterbilt owners who need dependable performance in extreme conditions

What sets it apart: Exceptional cold-weather starting capability and consistent output even under heavy loads

DB Electrical product review, alternator comparison

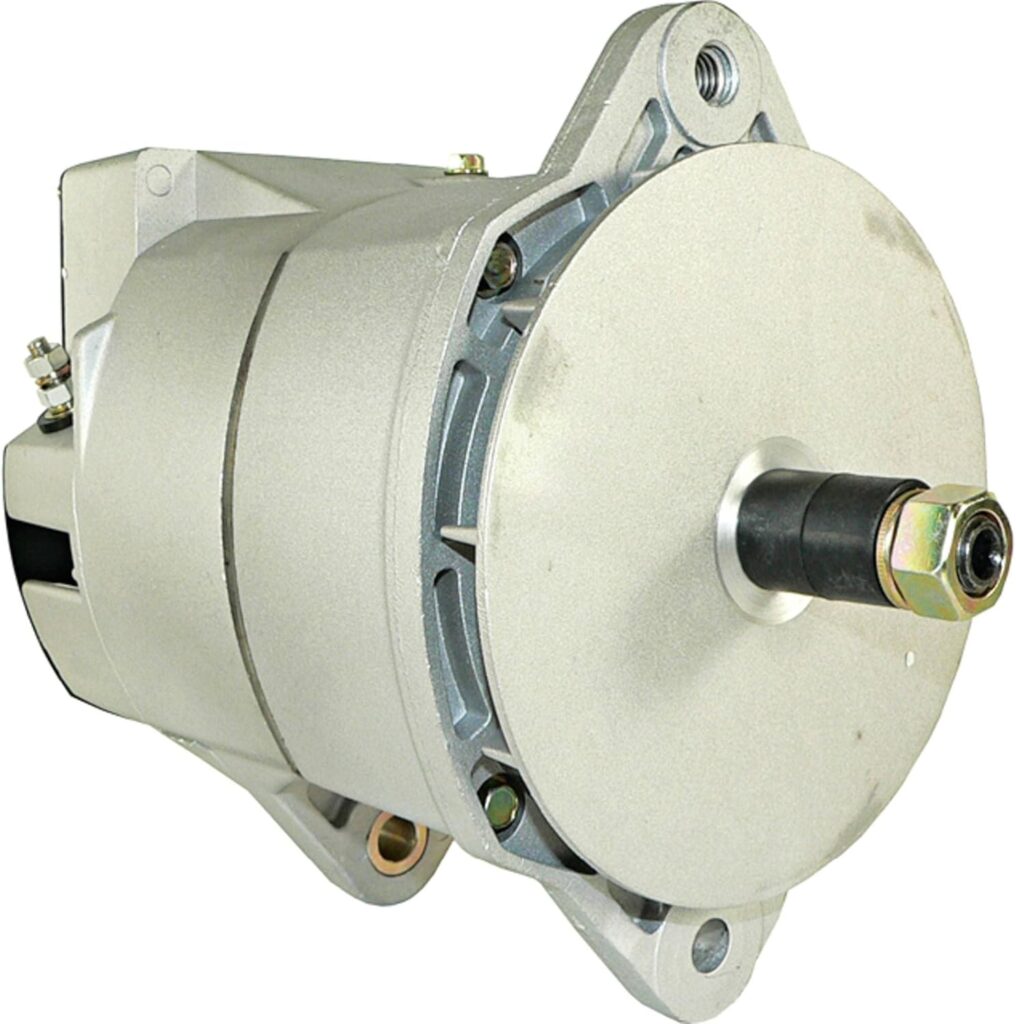

2. DB Electrical ADR0410: The Universal Favorite

Among my driving circle, this is often called “the last alternator you’ll buy.” Its robust construction and straightforward installation make it popular with both professional mechanics and DIY-minded owners.

Ideal for: Peterbilt, Freightliner, International, Kenworth, and Volvo trucks

What sets it apart: Outstanding heat dissipation keeps it running cooler than competitors, extending internal component life.

3. Valeo 439546: The Premium Option

If you’re willing to invest a bit more upfront, the Valeo delivers exceptional return through efficiency and longevity. I’ve seen these units still performing flawlessly after 500,000+ highway miles.

Ideal for: Owner-operators who plan to keep their trucks for many years

What sets it apart: OEM-quality construction with improvements in power efficiency over stock alternators

4. DB Electrical ADR0142: The Versatile Performer

This model shines in mixed-use applications where conditions can vary dramatically from day to day. Its adaptability makes it perfect for regional haulers who face changing environments.

Ideal for: Caterpillar, Ford, Kenworth, Peterbilt, Volvo, and Mack trucks

What sets it apart: Excellent surge capacity for handling variable electrical loads without stress

5. Denso 101211-8060: The Industry Standard

Denso has earned its reputation through decades of consistent quality. Their heavy-duty alternator costs more initially but typically requires zero maintenance throughout its extended lifespan.

Ideal for: High-mileage applications where reliability is non-negotiable

What sets it apart: Superior internal components and precision manufacturing result in whisper-quiet operation

DENSO Starters & Alternators

Installation Tips From Someone Who’s Done It Wrong (So You Don’t Have To)

Even the best alternator performs poorly when installed incorrectly. Here’s what I’ve learned:

Consider Professional Installation

Though I’m usually a DIY advocate, alternator installation involves critical electrical connections that directly impact your truck’s entire electrical system. The $150-200 labor cost often prevents much costlier problems down the road.

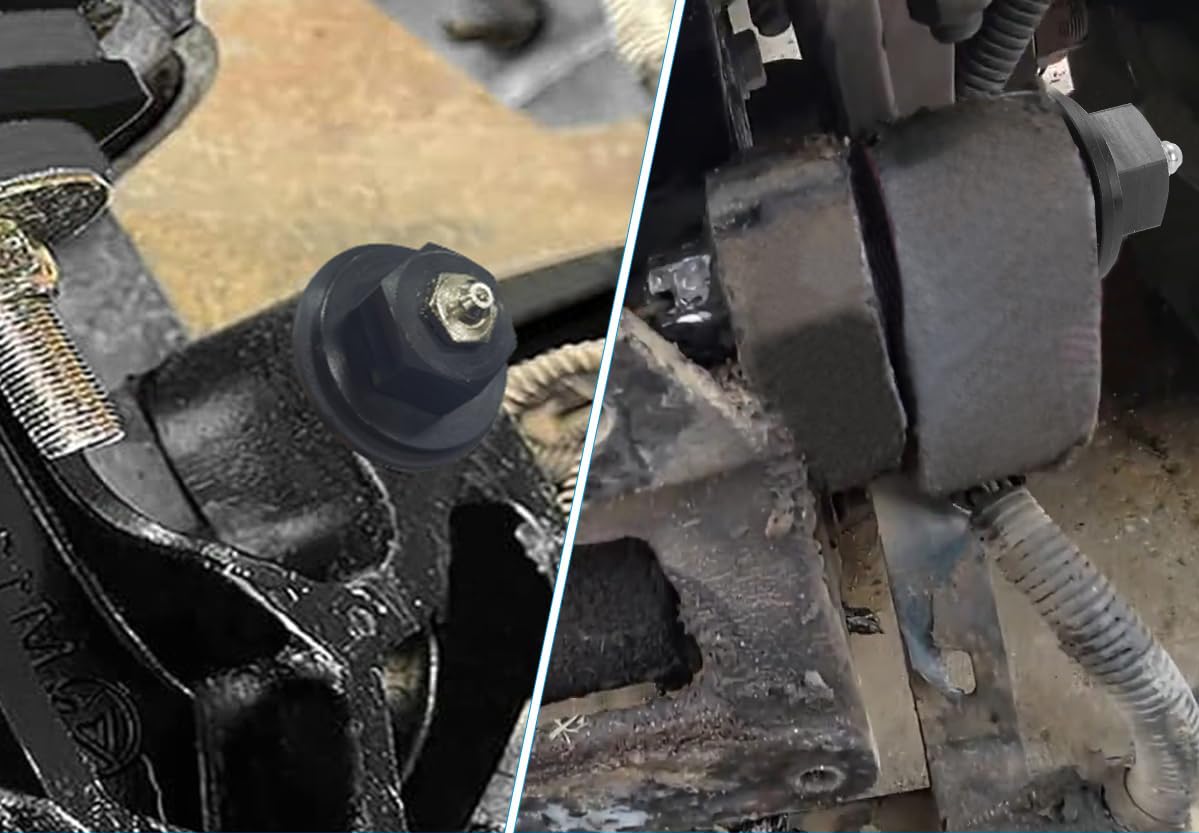

If You’re Installing Yourself:

- Disconnect the battery completely—no exceptions

- Check belt condition while the alternator is out—replace if showing any wear

- Clean all connection points thoroughly before installation

- Torque mounting bolts to exact specifications—over-tightening damages threads

- Use dielectric grease on all electrical connections

Extend Your Alternator’s Life

Simple maintenance dramatically extends alternator lifespan:

- Keep battery terminals clean and corrosion-free

- Check connections monthly for vibration loosening

- Listen for unusual bearing sounds—early intervention prevents catastrophic failure

- Address electrical issues immediately rather than hoping they’ll resolve

Best Alternator In 2025 – Top 10 Alternators Review

Making Your Final Decision

After years on the road, I’ve found that alternator selection comes down to three key factors:

- Your truck’s specific electrical demands

- The conditions you typically drive in

- How long you plan to keep your current rig

For most owner-operators, the DB Electrical models offer the best value-to-performance ratio. If you’re running a fleet with maintenance staff, the standardization benefits of Denso might save headaches down the road.

Whichever model you choose, remember that installation quality and regular maintenance matter just as much as the alternator itself. Take the time to do it right, and your truck’s electrical system will reward you with years of trouble-free operation.